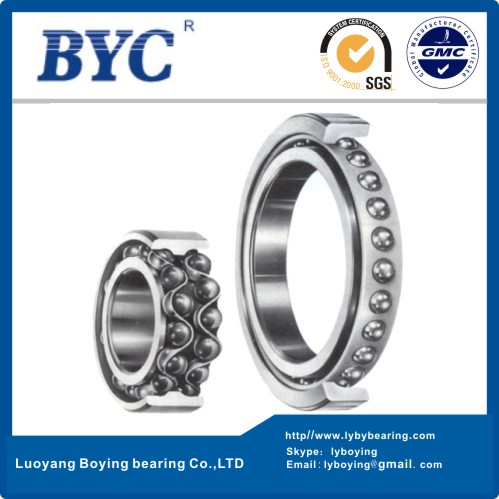

7000C P4 Angular Contact Ball Bearing (10x26x8mm) High Precision

7000C P4 Angular Contact Ball Bearing (10x26x8mm) High Precision

7000 Angular Contact Ball Bearing (10x26x8mm) Spindle bearings

A . Angular Contact Ball Bearing Parameters

Brand BYC

Structure Angular Contact

Model number 7000

Inner ring(mm) 10

Outer ring(mm) 26

Width(mm) 8

Weight(Kg) 0.023

Materials Chrome steel/GCR15

Precision grade P5/P4/P2

Lubrication type Grease lubrication

Contact Angle C=15°;AC=25°

Material(Ball) Steel ball(SUJ2); SN24:Ceramic ball(Si3N4)

Number of Row Single rows

Material(Cage) TYN-PA;TR-PF

Combination of mark SU:Universal combination (single row)

DU:Universal combination (double rows)

DB: Back-to-back combination

DF: Face-to-face combination

DT: Parallel combination

DBD.DFD.DTD: Three rows

DBB.DFF.DBT.DFT.DTT: Four rows

Preloaded mark EL: Micro preloaded

L : Light preload

M : Medium preloade

H : Heavy preloaded

B . 7001 Angular Contact Ball Bearing Specification Sheet

| Model Number | Dimensions | α=15° | α=25° | Material (Cage ) |

Weight (kg) Approx |

||||

| Limiting speed | Limiting speed | ||||||||

| d | D | B | Basic load rating | Lubrication | Basic load rating | Lubrication | |||

| Cr Cor | Grease Oil | Cr Cor | Grease Oil | ||||||

| 7000 | 10 | 26 | 8 | 4.0 2.4 | 66000 90000 | 3.8 2.3 | 59000 89000 | PA/PF | 0.023 |

C . 70 series Angular Contact Ball Bearing Details

Product Features Precision Angular Contact Ball BearingsDue to their internal design, angular contact ball bearings can withstand high radial-axial loads and reach high speeds. They are asymmetrical for manufacturing reasons and can withstand unidirectional axial loads

only. Angular bearings are usually mounted in a group of two or more opposed preloaded units with rigid or elastic spacers.

Typically, the inner and outer raceways and balls are made of chrome steel. Where operating conditions are severe, bearings

may have ceramic balls creating a hybrid bearing.

Series Introduction ISO 10 Series - highest load, second lowest speed bearings-70 Series Angular Contact Bearings

Series Model No.7000, 7001, 7002, 7003, 7004, 7005, 7006, 7007, 7008, 7009, 7010, 7011, 7012, 7013, 7014, 7015,7016, 7017, 7018, 7019, 7020,7021, 7022, 7024, 7026, 7028, 7030, 7032, 7034,7036, 7038, 7040, 7044, 7048, 7052, 7056, 7060, 7064, 7068, 7072, 7076, 7080, 7084

Applications "Angular contact bearing applications :

electric motors,Spindle,automotive applications, home appliances, industrial equipment."

D . 70 series Angular Contact Ball Bearing Installation & Cautions

"Installation:

To obtain the best possible performance of the bearings, installation must be performed very carefully in ultra clean conditions.

Errors during fitting of ball bearings can jeopardize the best design and create high repair and maintenance costs. We would like to give some advise for proper mounting of bearings:

The workshop should be dust free with low humidity, no compressed air or machining is allowed.

Only unpack bearings immediately before installation. If grease is required it should be applied at this time, with a syringe. Do not use fingers or a spatula.

The use of a syringe is recommended to inject the grease right between the balls into the ball/raceway area. Nearly all standard greases are compatible to our rust preventive, so in most cases it is not necessary to wash the bearings prior to greasing. The only exceptions are special greases, based on silicone or fluorocarbon oils or PTFE-thickeners. They require a clean oil free surface to obtain good adhesion of the grease.

Never clean the bearings in ultra sonic devices! Allow the rust preventive to dissolve in a gasoline bath by slowly moving the bearings."

E . Our Best Bearing Service

"Angular contact ball bearings features :

1) Load capacities are higher than deep groove ball bearings of same dimensions

2) Used for bearing radial-axial combined loads or pure thrust loads

3) Low operating friction and high limiting speed The follow is our products:

1. High precision Angular contact ball bearings

2. Thin-section ball bearings

3. High precision Thin-section crossed roller bearings Shipping And Payment

1. Industrial Neutral Packing,Package as your requirements.

2. Small size Bearings:Plastic vacuum packaging bag+Paper Box/Neutral Carton

3.Large size Bearings:Plastic film+ paper+Roll tape+Wooden Box

4.Shipping:By air or By sea:DHL/TNT/UPS/EMS etc The leading products include

crossed roller bearing RB, RE, RU,RA,CRBC, CRBH, XSU, SX series, rotary table

bearings YRT, YRTS,YRTM,ZKLDF series, crossed tapered roller bearing JXR, XR

series, cylindrical roller thrust bearing 811 series, almost whole range of precision

bearings. The accuracy grades are P5, P4, P2, and the size of inner ring are ranging

from Φ50mm --- Φ1300mm Our products are optimal for applications such as joints and swiveling

Share this product to:

Let more people see your product

Let more people see your product

High quality 7000C ( 0.023 kg Mass, ID: 10 mm OD: 26 mm WD: 8 mm , P5/P4/P2 Accuracy Class , Chrome steel/GCR15 Material ), Just click the button " Contact Now " to mention your purchase Requirement , Quantity and Contact Method of your requested Bearing Item No. 7000C. then click the button " Send " The web site will make your purchasing information sent to the supplier's mailbox, who will come to contact you upon they get your information at the first time.

7000C Related Products »

-

- 7001AC P4 Angular Contact Ball Bearing (12x28x8mm) Spindle bearings

- Model number 7001 Inner ring(mm) 12 Outer ring(mm) 28 Width(mm) 8 Weight(Kg) 0.025 Materials Chrome steel/GCR15 Precision grade P5/P4/P2

-

- 7000C P4 Angular Contact Ball Bearing (10x26x8mm) High precision

- Model number 7000 Inner ring(mm) 10 Outer ring(mm) 26 Width(mm) 8 Weight(Kg) 0.023 Materials Chrome steel/GCR15 Precision grade P5/P4/P2

-

- 7002AC/C DBP4 Angular Contact Ball Bearing (15x32x9mm) Ceramic Ball Bearings

- Brand BYC Structure Angular Contact Model number 7002 Inner ring(mm) 15 Outer ring(mm) 32 Width(mm) 9 Weight(Kg) 0.035

-

- 7003AC/CTYN Angular Contact Ball Bearing (17x35x10mm) Ceramic Ball Bearings

- Brand BYC Structure Angular Contact Model number 7003 Inner ring(mm) 17 Outer ring(mm) 35 Width(mm) 10 Weight(Kg) 0.046

-

- SX011814 crossed roller bearing|thin section slewing bearing|70*90*10mm

- Quick Details · Type: Slewing Bearing · Brand Name: BYC · Bore Size: 70 mm ·

-

- SX011818 crossed roller bearing|thin section slewing bearing|90*115*13mm

- SX011818 crossed roller bearing|Thin section bearings|BYC slewing ring bearings with good price

-

- SX011820 crossed roller bearing|thin section slewing bearing|100*125*13mm

- SX011820 crossed roller bearing|Thin section bearings|slewing ring bearings price (Separable Outer Ring,

-

- SX011824 crossed roller bearing|thin section slewing bearing|120*150*16mm

- SX011824 crossed roller bearing|Thin section bearings|bearing matching size for Robotic (Separable Outer