1.5mm Ceramic Balls (zirconia)

Reference FOB Price:

US1 ~ 9999 / Piece

Min. Order:

1 Piece

Stock:

2147483647 Piece

Production Capacity:

110000000000000000

Port:

Zhongshan

Payment term:

TT/Western Union

Delivery time:

7 days after payment

Technical Parameters:

Product Designations:

1.5mm Ceramic Balls (zirconia)

Structure:

bearing accessories

Inside Diameter:

1.5 mm

Outside Diameter:

1.5 mm

Thickness:

1.5 mm

Weight:

according to different size KG KG

Demensions:

1.5mm

Brand:

HRT

Precision Rating:

G10

Bearing Material:

zirconia

Seals Type:

non heat treatment

Ball Material:

zirconia

Shipping Ways:

EXW

Feature:

Good wearing, excellent surface quality, and high hardness.

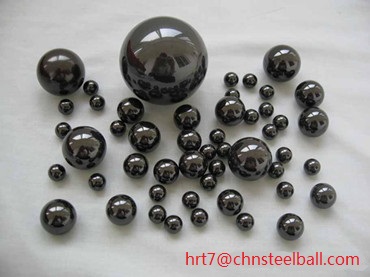

1.5mm Ceramic Balls (zirconia)

ceramic balls (zirconia, black)

Material: zirconia

Size: 1.5mm

Grade: G3/G5/G10

Applications: ceramic aerospace bearings, agitator balls, ceramic automotive bearings, conveyors balls, spring loaded balls

Zirconia balls feature resistance to abrasion and corrosion and are chemically inert to molten metals, organic solvents, caustics, and most acids. In addition, zirconia balls maintain high strength at temperatures up to 982ºC (1800 ºF).

Ceramic Balls Information

Ceramic balls are spherical, rolling elements that provide higher stiffness, lower thermal expansion, lighter weight, increased corrosion resistance, and higher electrical resistance than steel balls. They are made from a variety of ceramic materials.How Ceramic Balls are Made

Ceramic balls are manufactured by pressing a ceramic powder binder mixture in a preform shape. After the ball is sintered, the part lines are removed via finish-grinding. Lapping and precision finishing is then used to design or grade dimensions and product specifications such as diameter, sphericity, and surface finish. For applications that require a fully-dense material with specific material properties, hot isostatic pressing (HIP) may be used after sintering. HIP produces ceramic balls with a pore-free microstructure and micron-sized grains.

Applications for Ceramic Balls

The GlobalSpec SpecSearch database contains information about applications for ceramic balls, many of which are used as bearings. The following list provides some examples.

· Ceramic aerospace bearings are used in airframes as well as gyroscopes (gyros), navigation systems, flow meters, avionic instruments, and other aerospace parts.

· Agitator balls have suitable corrosion and density (weight) for agitation or mixing applications, such as the balls used in aerosol paint cans.

· Ceramic automotive bearings are used with seating tracks and seat slides, safety restraints and seatbelt locking mechanisms, airbags, constant velocity (CV) joints, double offset joints, tripod joints, cross groove joints, spindle bearings, and many other systems.

· Conveyors balls are used in conveyors, ball transfer units, roller table, casters, roller or lazy Susan applications.

· Spring loaded balls are used in quick disconnect couplings or snap on fasteners and fastening systems. Socket wrenches often use this type of fastening mechanism to hold onto the socket.

Ceramic balls are also used in float or level sensing, flow metering, gaging or alignment, valves, sprayers and pumps, and pollution or vapor control systems.

Share this product to:

Let more people see your product

Let more people see your product

How can you buy 1.5mm Ceramic Balls (zirconia) on the Internet?

High quality 1.5mm Ceramic Balls (zirconia) ( according to different size KG kg Mass, ID: 1.5 mm OD: 1.5 mm WD: 1.5 mm , G10 Accuracy Class , zirconia Material ), Just click the button " Contact Now " to mention your purchase Requirement , Quantity and Contact Method of your requested Bearing Item No. 1.5mm Ceramic Balls (zirconia). then click the button " Send " The web site will make your purchasing information sent to the supplier's mailbox, who will come to contact you upon they get your information at the first time.

High quality 1.5mm Ceramic Balls (zirconia) ( according to different size KG kg Mass, ID: 1.5 mm OD: 1.5 mm WD: 1.5 mm , G10 Accuracy Class , zirconia Material ), Just click the button " Contact Now " to mention your purchase Requirement , Quantity and Contact Method of your requested Bearing Item No. 1.5mm Ceramic Balls (zirconia). then click the button " Send " The web site will make your purchasing information sent to the supplier's mailbox, who will come to contact you upon they get your information at the first time.

Previous Product: 1.2mm Ceramic Balls (zirconia)

Next Product: 2mm Ceramic Balls (zirconia)

Categories: Bearing Balls

1.5mm Ceramic Balls (zirconia) Related Products »

-

- 0.8mm Ceramic Balls (zirconia)

- ceramic balls (zirconia, black) Material: zirconia Size: 0.8mm Grade: G3/G5/G10 Applications: ceramic aerospace bearings, agitator balls,

-

- 1mm Ceramic Balls (zirconia)

- ceramic balls (zirconia, black) Material: zirconia Size:1mm Grade: G3/G5/G10

-

- 1.2mm Ceramic Balls (zirconia)

- ceramic balls (zirconia, black) Material: zirconia Size:1.2mm Grade: G3/G5/G10

-

- 1.5mm Ceramic Balls (zirconia)

- ceramic balls (zirconia, black) Material: zirconia Size:1.5mm Grade: G3/G5/G10

-

- Chrome steel ball 1.2mm G10

- 1.2mm Chrome Steel Ball AISI52100/SUJ-2 Material: chrome steel AISI52100/SUJ-2 Size: 1.2mm Grade: G10~G1000 Hardness: HRC62-65. Certificate: ISO-9001,TS-16949,

-

- Chrome steel ball1.0mm G10

- 1.0mm Chrome Steel Ball AISI52100/SUJ-2 Material: chrome steel AISI52100/SUJ-2 Size: 1mm Grade: G10~G1000 Hardness: HRC62-65. Certificate: ISO-9001,TS-16949,

-

- Chrome steel ball 0.8mm G10

- 1.Stainless Steel Ball (AISI304) 2.Size: 0.8mm 3.Grade: G10 4.Hardness:HRC62-65 5.General Application: Bearings,Automotive,Castors,,Welding,Capabilities decorative,bicyc

-

- Chrome steel ball 0.7937mm G20

- 1.Chrome Steel Ball (AISI304) 2.Size: 0.7937mm 3.Grade: G20 4.Hardness: HRC62-65. 5.General Application: Bearings,Automotive,Castors,,Welding,Capabilities